CVD and HPHT Diamonds, Explained

The mined diamond lobby is hell-bent on creating numerous misconceptions about lab-created diamonds. Even the written content marketed by many traditional diamond education websites carries a negative tone even when they explain about the technology used to create lab-grown diamonds. Probably the two most less understood terms related to lab-grown diamonds are CVD and HPHT.

The CVD and HPHT are two different technologies used to create lab-grown diamonds, but understanding the fundamental differences between the processes is important.

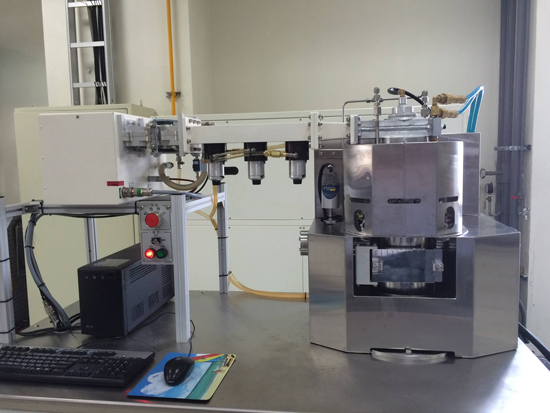

HTPT Chamber

HPHT

HPHT stands for high pressure – high temperature, a term referring to the use of heated pressure chambers to create diamonds. This is the method used by General Electrical to create first grown diamonds in 1954. Later, the technique became popular among mined diamond producers to enhance the color of poor-quality mined diamonds. Hence, when you notice HPHT mentioned against the comments on a diamond certificate, it does not necessarily mean it is a lab-created diamond. If the certificate says the diamond is a mined one, then HPHT implies that the diamond, which initially had an inferior quality undergone color and clarity enhancement.

Imagine a large pressure cooker cooking diamonds out of graphite and small diamond seeds. Small mined diamond seeds are placed inside the growth chamber with graphite inserted on top of them. The temperature is increased to 1500 centigrade and pressurized to approximately 70,000 times the pressure at sea level. In other words, it is a technological recreation of the same conditions in the earth's crust that turns carbon into diamonds. The main problem with the HPHT method is that it is costly and not very green when it comes to energy consumption.

CVD

CVD stands for chemical vapor deposition, a much smarter and greener technology that underwent significant developments recently. The process carried out in a vacuum chamber (plasma reactor), with a thin diamond film, is placed, and hydrocarbon gas is injected into the chamber during the process. The hydrocarbon gas molecules are broken by high powered microwaves making carbon atoms precipitate on the diamond films building the diamond lattice atom by atom.

If you imagine a large microwave oven, that lets carbon precipitate like snow on a diamond film, turning it into a bigger diamond – that is how the CVD process work. Since the diamond growing is driven by kinetics, unlike the thermodynamics as in HPHT or natural creation, the process consumes much less energy. Besides, the process gives greater control over the raw materials (the gases), enabling the growth of diamonds of absolute purity.

CVD Chamber

At Hatch Brilliance, 99.99% of our diamonds are created using CVD technology. The certificate comes with each diamond clearly state the fact. After all, a diamond is born when one more carbon atom added to the graphite crystal. Mining diamonds is simply a technology of digging out diamonds from the earth by a process that is permanently damaging to Mother Nature. We embrace a technology that is sustainable and greener that creates the same miracle – the diamonds.

Minded Diamond Growing

HPHT Diamond Growing

CVD Diamond Growing

Image Courtesy: Ringspo